Poké Ball

Background

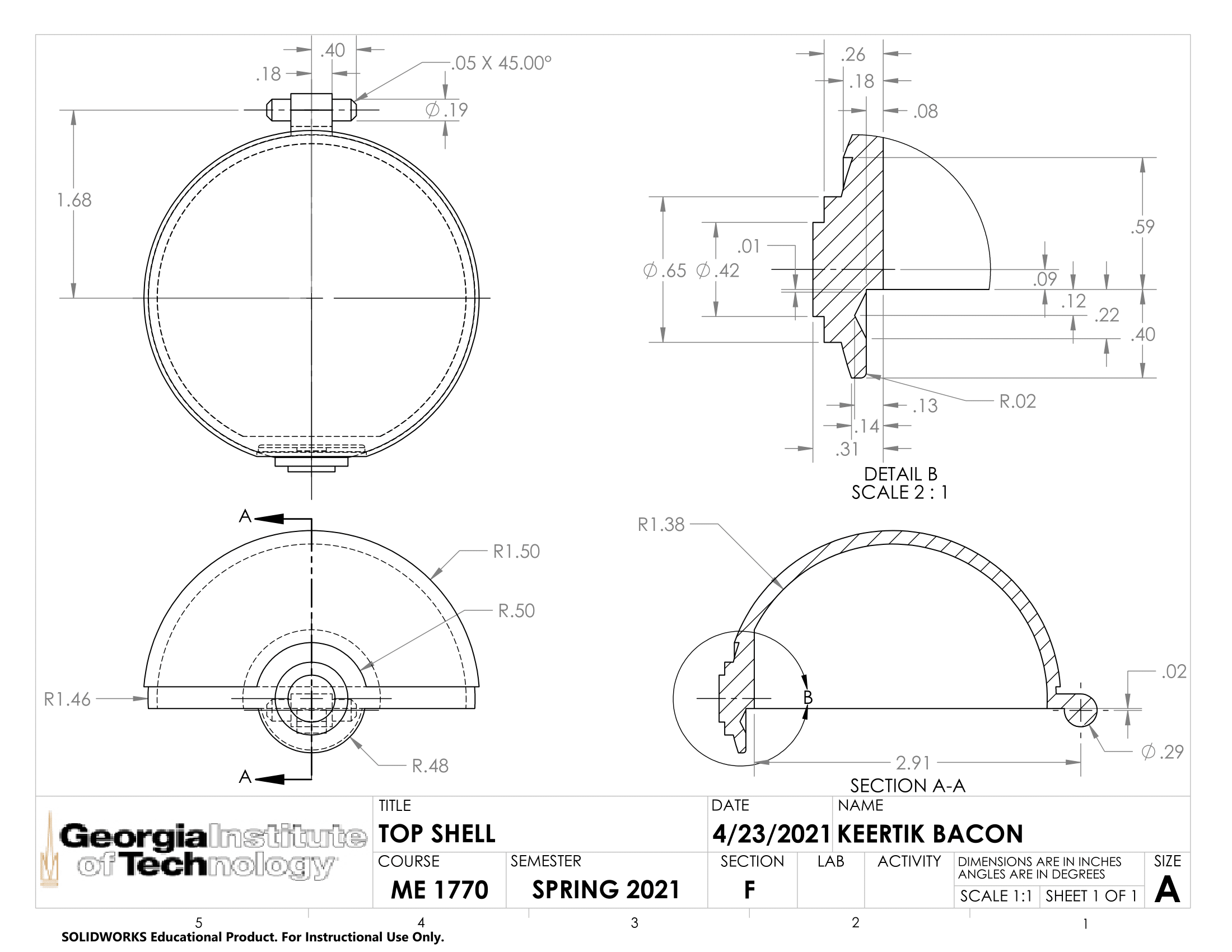

ME 1770 is the introductory engineering visualization class at Georgia Tech, where we learn how to sketch product concepts and design using SolidWorks computer-aided design software. In addition to a group design project, the class also has an individual project, in which we are tasked with designing an item with several interlocking parts. Our item would then be 3D printed using an SLS printer, and then we would assemble our parts to see how well the interlocking parts fit together.

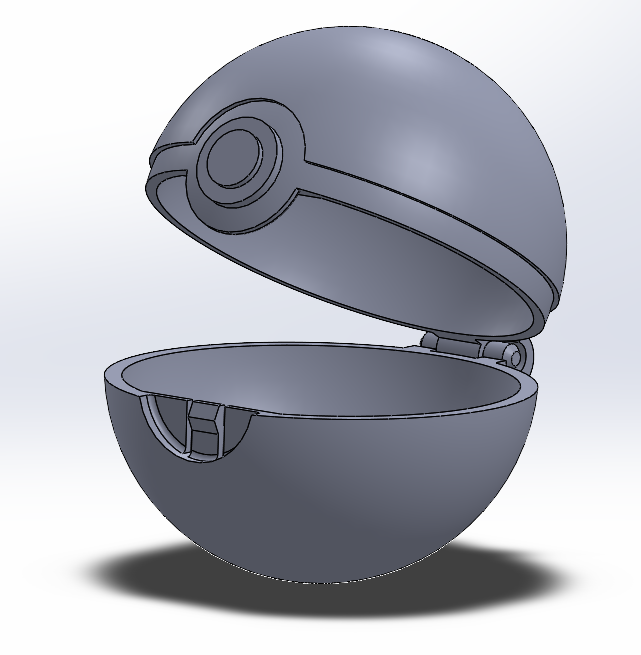

I took the class in Spring 2021, and, being a big Pokémon fan, decided to make a Poké Ball for my individual project. I envisioned it as a nice little box to hold things, and designed it accordingly.

Design

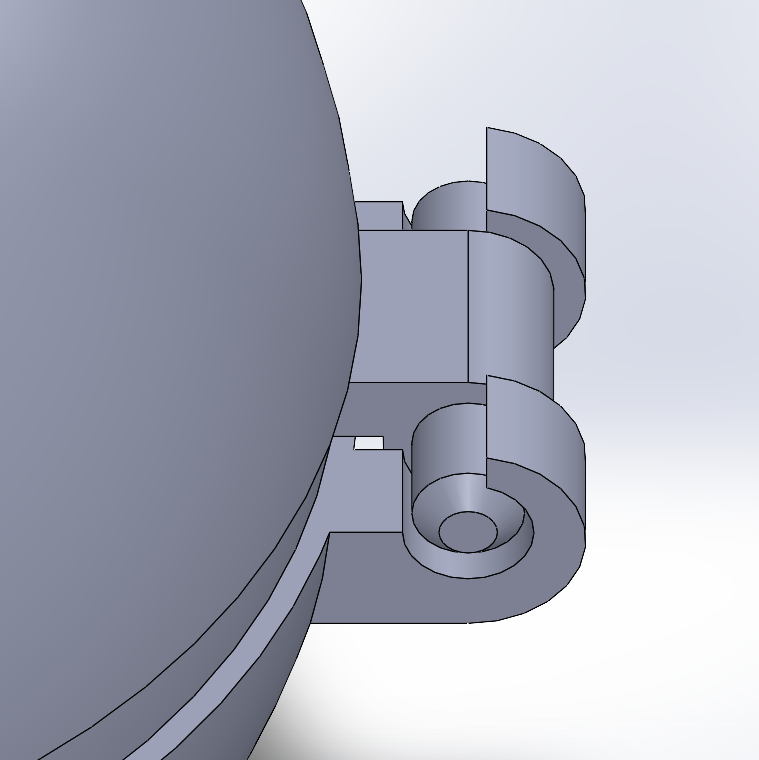

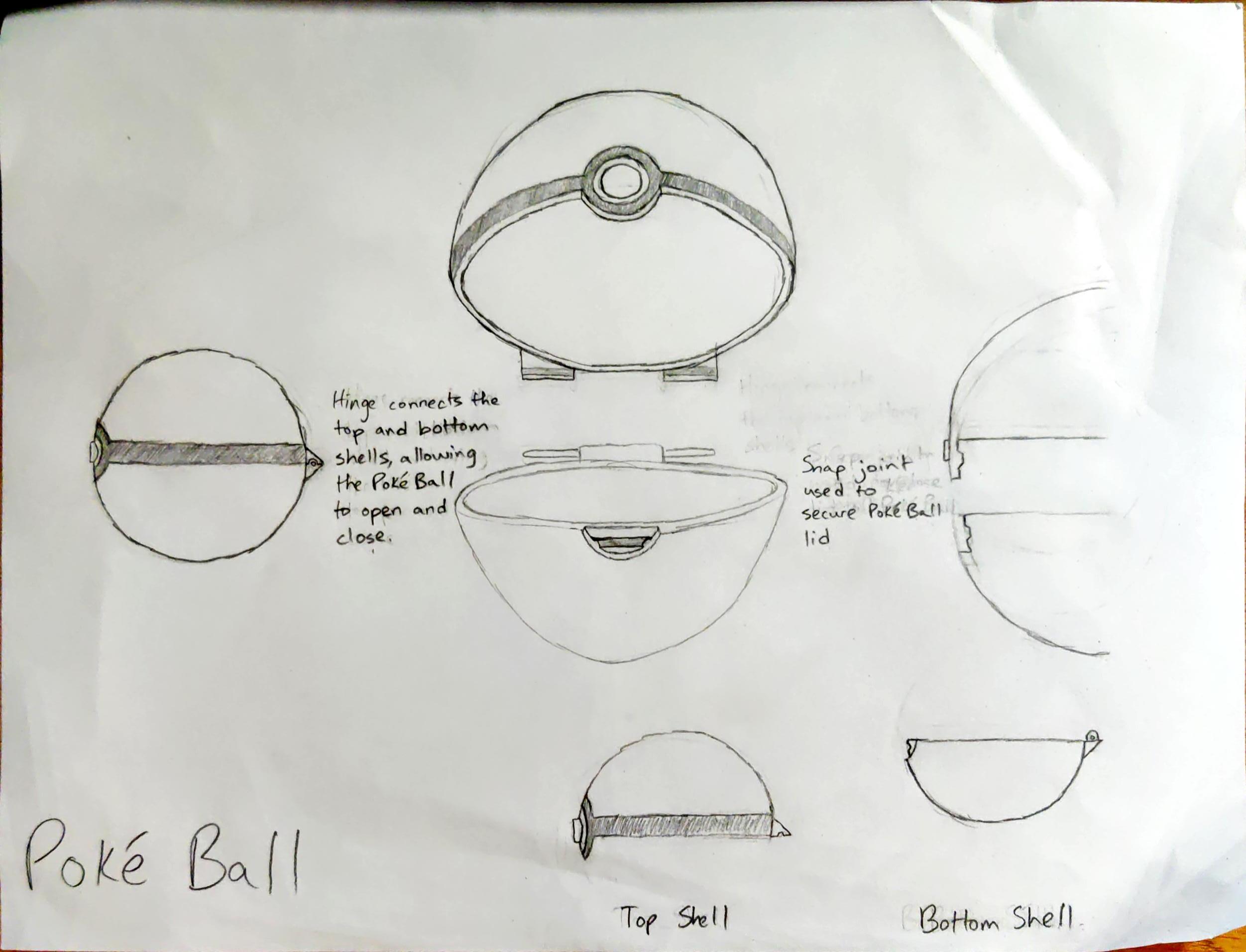

Going into the design process, my biggest concern was regarding the interlocking features. I knew there needed to be a hinge at the back, but it couldn't be too large, as I wanted to make my design faithful to the Poké Balls from the video games and TV series. Those Poké Balls have very hidden hinges, so I had to try and make the hinges on mine more understated.

The Poké Ball would also need to snap closed, as otherwise it would be useless as a storage container. I initially wanted to make a mechanism that would open the ball when the center button was pressed, but I couldn't figure out how to design that, so I went with a separable snap fit that connects the 2 halves of the ball together all the center circular section.

Results